In the world of corporate gifting, the most common request I have to reject is also the most seemingly simple: "Can you just print our pattern all the way to the edge of this notebook?"

The answer is always no. And it’s not because we’re being difficult. It’s because of geometry.

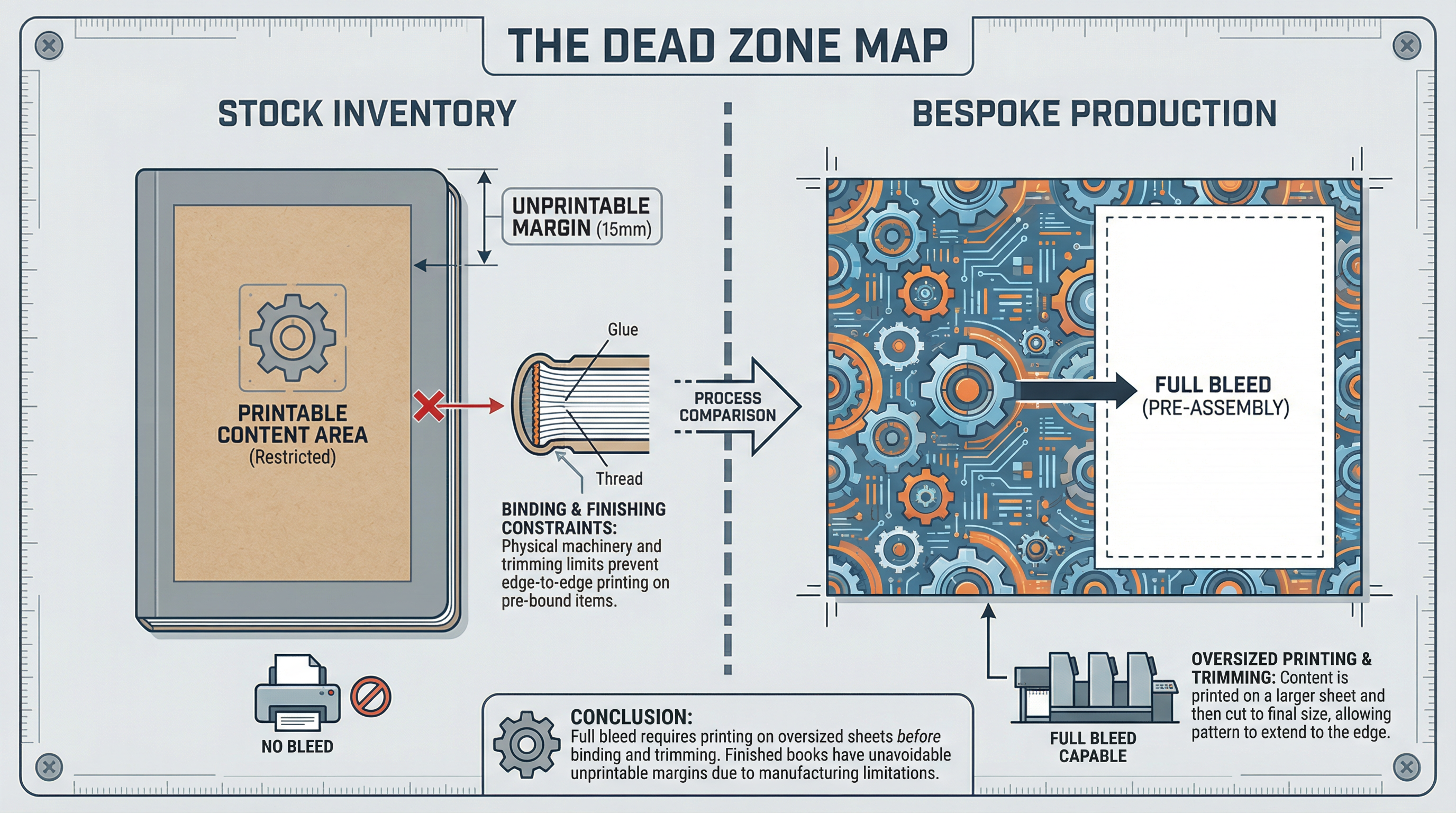

There is a critical misunderstanding in the customization process between "Post-Production Customization" (what we do to a finished book) and "Pre-Assembly Manufacturing" (what we do to a flat sheet). Confusing the two is the "Full Bleed Trap."

The Geometry of the Finished Edge

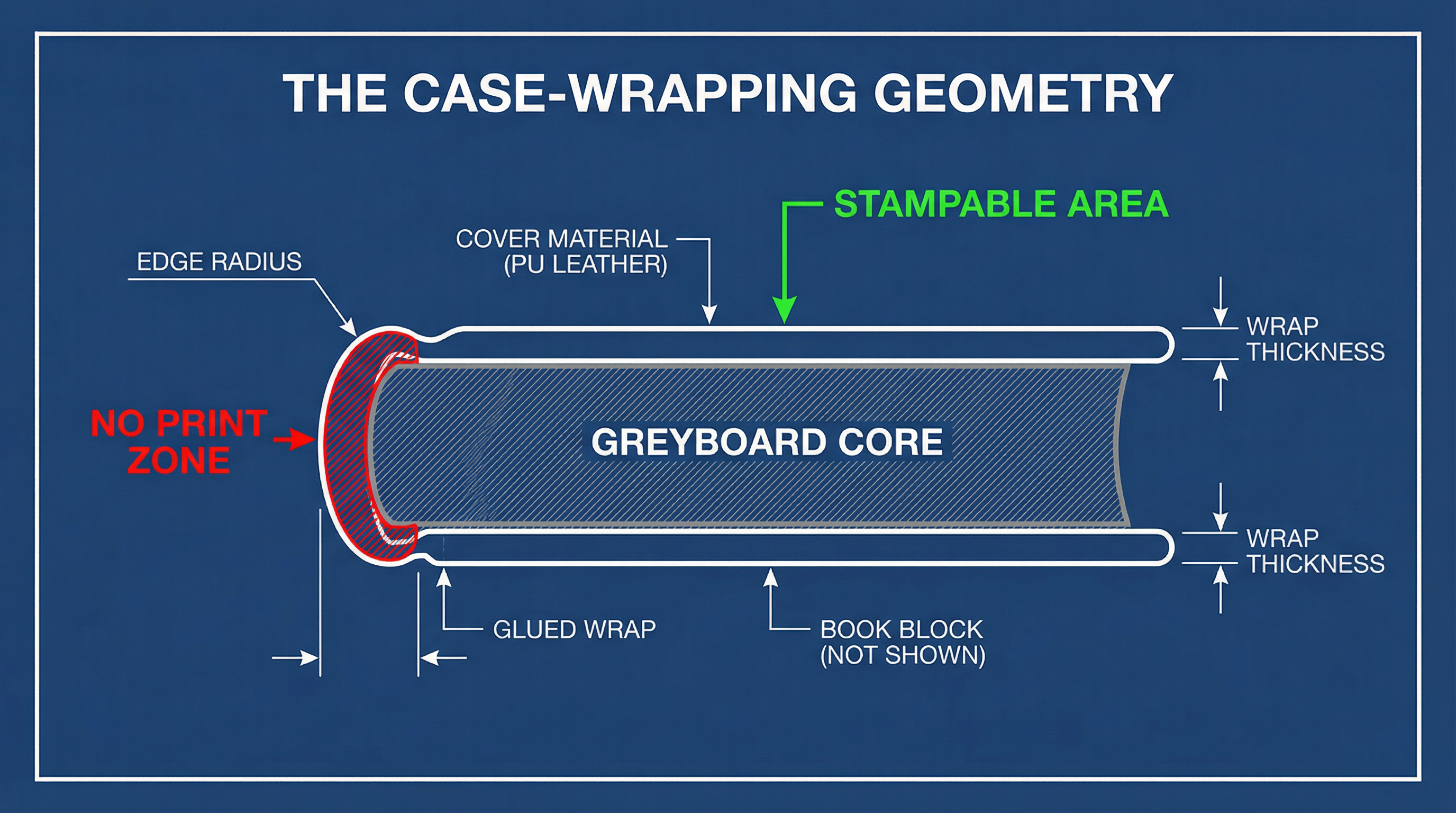

To understand why we can't print to the edge of a stock notebook, you have to look at how a book is built. The cover isn't a flat surface; it's a three-dimensional object wrapped around a rigid greyboard core.

The cover material (PU leather or paper) wraps around the edge of the board and is glued to the inside. This creates a curved radius at the edge. A digital printer head or a hot stamping die is flat. It cannot wrap around a curve. It needs a flat, stable surface to apply pressure.

In practice, this is often where customization decisions start to be misjudged. If we try to stamp right to the edge, the die slips off the curve, resulting in uneven pressure, crushed edges, and a rejected product. This is why every stock notebook has a mandatory "safe margin"—usually 15mm to 20mm from the edge—where no artwork can go.

The "Dead Zone" vs. True Full Bleed

So, how do you see notebooks with edge-to-edge patterns in retail stores? They weren't printed after they were books. They were printed before they were books.

True "Full Bleed" requires Pre-Assembly Manufacturing. We take a large, flat sheet of PU leather, print the pattern on it (oversized), and then cut it, wrap it around the board, and glue it. The pattern wraps around the edge because the material itself is patterned.

This is the trade-off. If you want full bleed, you are not buying a "customized stock notebook." You are commissioning a "bespoke manufacturing run." This changes everything:

| Feature | Stock Customization (Post-Production) | Bespoke Manufacturing (Pre-Assembly) |

|---|---|---|

| Full Bleed? | Impossible | Standard |

| MOQ | Low (50+ units) | High (500-1,000+ units) |

| Lead Time | Fast (2-3 weeks) | Slow (8-12 weeks) |

The Strategic Choice

The "Full Bleed Trap" happens when a brand wants the look of Bespoke Manufacturing with the budget and timeline of Stock Customization. It is physically impossible.

If your design relies on a pattern that bleeds off the edge, you have two choices:

1. Commit to Scale: Increase your order to 1,000 units and wait 10 weeks for bespoke production.

2. Adapt the Design: Reframe your artwork to sit centrally within the 15mm safe margin of a stock notebook.

Conclusion

Don't fight the geometry. Understanding the difference between a finished object and a raw material is the key to realistic procurement. If you need it fast, respect the margin. If you need the bleed, respect the timeline.