Production Engineering Insight

The Manual Insertion Bottleneck: Why 'Tip-In' Pages Disrupt Automated Binding

In high-volume notebook manufacturing, the most common misconception from procurement teams is that adding a single customized page—often called a "tip-in" or "advertising page"—is a minor adjustment. The assumption is that since the machine is already collating hundreds of pages, inserting one more should be negligible.

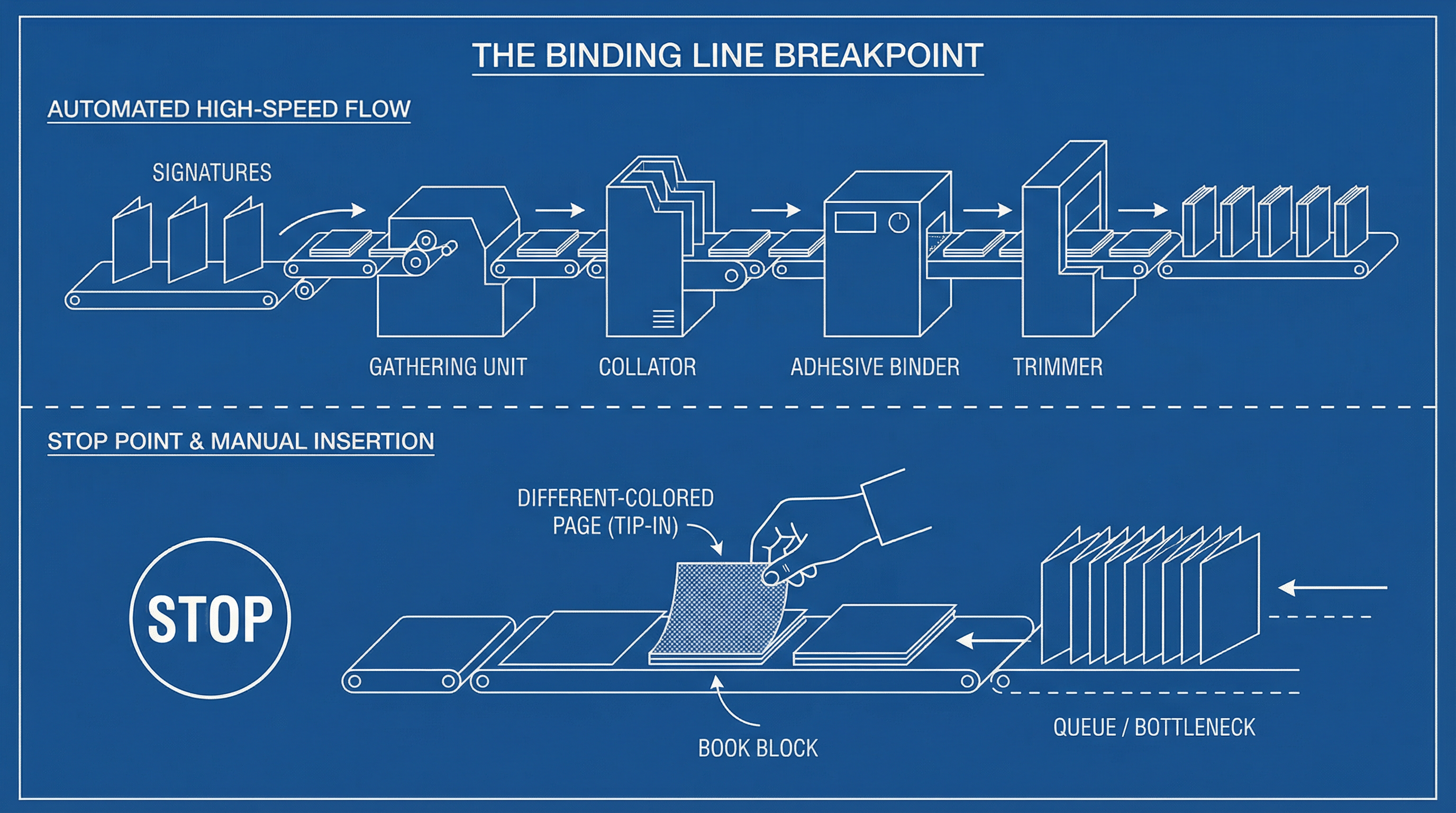

From the factory floor perspective, however, a tip-in page is not an addition; it is an interruption. Standard notebook blocks are produced using high-speed gathering machines that collate folded signatures (groups of 16 or 32 pages) at rates exceeding 4,000 cycles per hour. These machines are calibrated for uniform paper weights and signature thicknesses.

When a specification calls for a single, distinct sheet—often of a different paper stock, gloss finish, or print method—to be inserted at a specific location (e.g., right after the front endpaper), the automated gathering line cannot handle it. The friction coefficient of a single glossy sheet differs from the uncoated book block, causing misfeeds and jams in high-speed feeders.

The Transition to Manual Handling

Consequently, the decision to include a tip-in page forces the production line to decouple. The automated gathering process must be halted or bypassed for that specific section. Instead of a continuous flow from gathering to sewing, the book blocks must be offloaded and transported to a manual insertion station.

Here, operators must physically open each book block and glue the tip-in page by hand along the spine edge. This introduces two critical risks: human error in placement and inconsistency in glue application. A machine applies a precise, micron-thin layer of adhesive; a human operator using a brush or a semi-automated gluing machine cannot achieve the same uniformity.

This manual intervention is the primary reason why lead times for projects with tip-in pages often extend by 7 to 10 days compared to standard custom notebooks. It is not the printing of the page that takes time, but the disruption of the binding workflow. The "flow" of the factory is broken, turning a streamlined manufacturing process into a batch-and-queue operation.

Structural Implications of the Glue Line

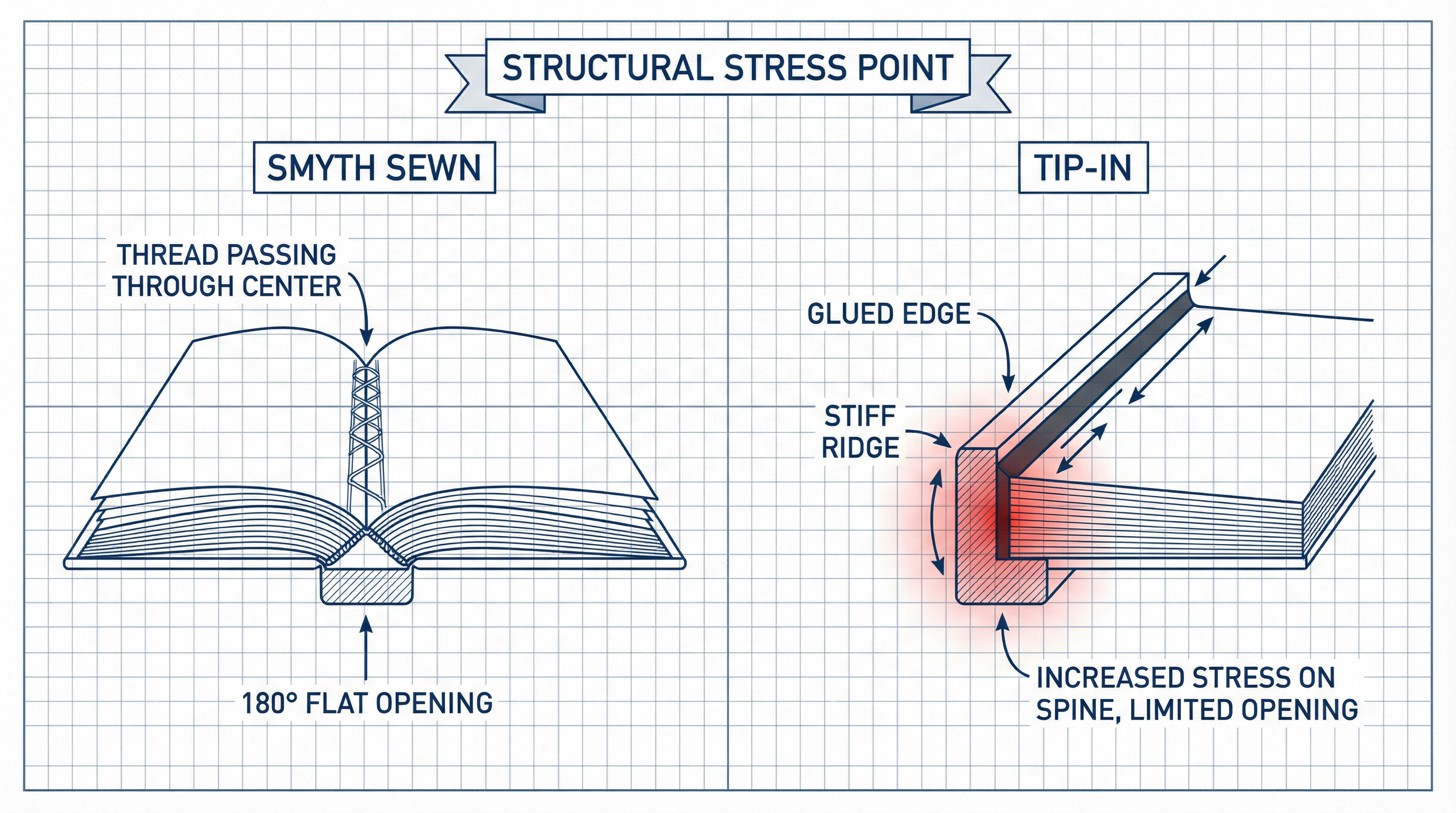

Beyond the timeline, the method of attachment fundamentally alters the physical behavior of the notebook. A standard high-quality notebook uses Smyth sewing, where thread passes through the center fold of the signatures. This allows the book to open 180 degrees and lie flat on a desk.

A tip-in page, by definition, has no fold to sew through. It is attached via a narrow strip of adhesive (usually 3-5mm wide) to the adjacent page. This creates a stiff "ridge" near the spine. When the user attempts to open the book at that specific page, the glue line resists the opening action.

In practice, this is often where Customization Process decisions start to be misjudged. The desire for a high-impact marketing message on the first page inadvertently compromises the functional "lay-flat" quality that defines a premium writing experience. The stress concentrated at this glue line also makes the page more susceptible to detaching if the book is forced open too aggressively.

Designing for Automation

To mitigate these issues while retaining the ability to include custom content, we often advise integrating the custom content into the signature itself. If the custom content can be designed as a 4-page, 8-page, or 16-page section (a full signature), it can be printed on the same paper stock as the rest of the book and fed into the automated gathering line just like any other section.

This approach restores the automated workflow, eliminates the manual gluing risk, and ensures the custom pages are sewn into the binding, preserving the lay-flat integrity. While it requires generating more content to fill a 4-page or 8-page section, the gain in production reliability and structural quality is substantial.

For procurement teams, understanding that "one page" is operationally more complex than "four pages" is key to optimizing both unit cost and delivery reliability. The goal is to design customization that works with the machinery, not against it.