In my fifteen years managing production lines, the most expensive mistakes I have witnessed all started with the same sentence: "But it looked perfect on the PDF."

There is a fundamental disconnect in the procurement process. We make decisions based on backlit, high-resolution screens, but we manufacture physical objects that interact with light, texture, and chemistry. This gap—the "Digital Mirage"—is where the customization process often breaks down.

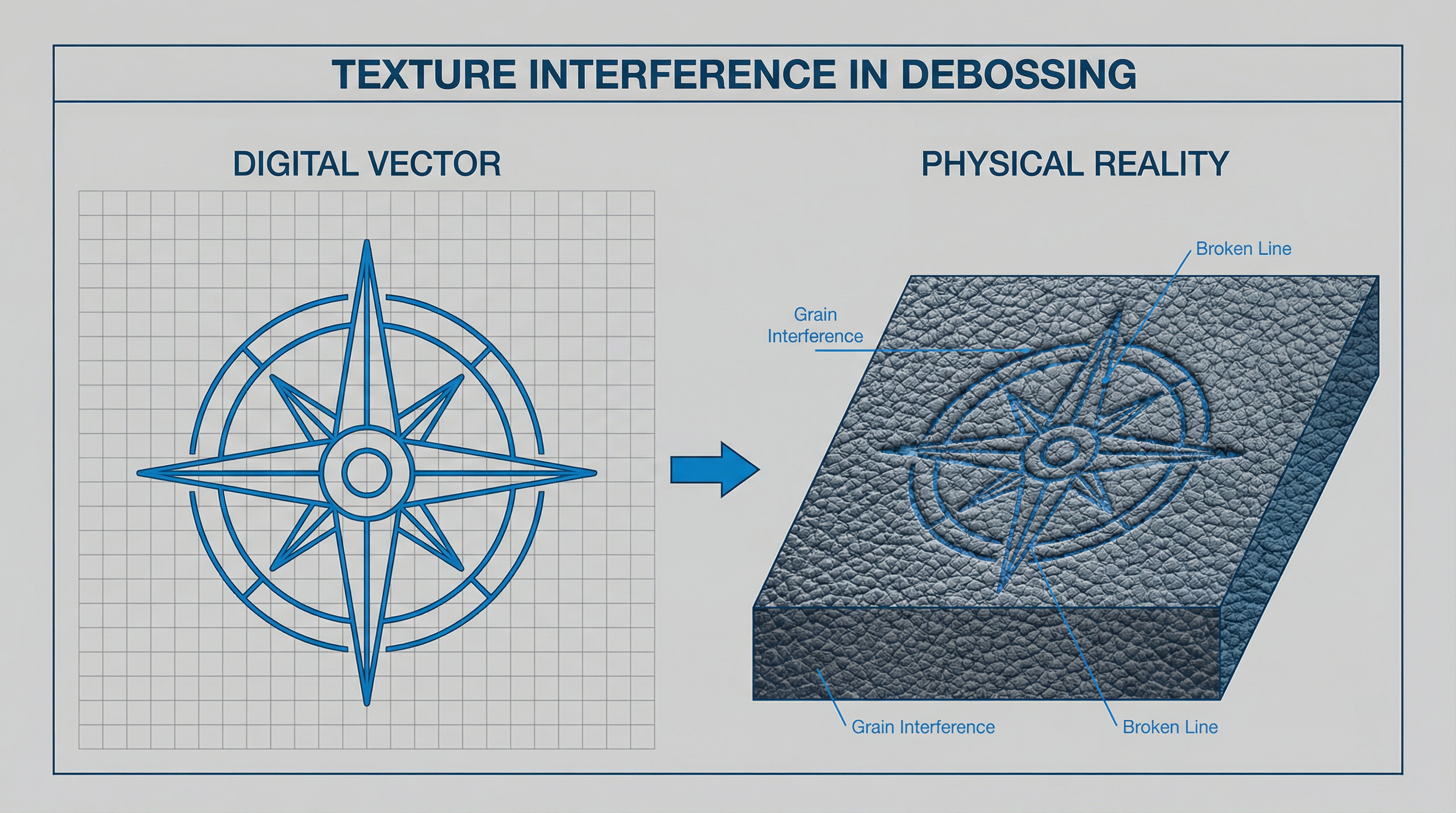

The Physics of Texture Interference

A PDF is a flat plane. It assumes the substrate (the material you are printing on) is a perfect, frictionless void. In reality, every premium notebook cover has a grain—a landscape of peaks and valleys.

When we look at a digital proof, we see clean, sharp vector lines. But when we apply a heated magnesium die to a pebbled leather surface, those lines encounter resistance. If a line is thinner than the grain of the leather (typically under 0.5mm), it doesn't just sit on top; it falls into the valleys or gets crushed by the peaks.

In practice, this is often where customization decisions start to be misjudged. A logo that looks elegant on a screen becomes illegible on the product because the physical grain "interferes" with the geometric perfection of the design. The PDF cannot simulate this mechanical conflict.

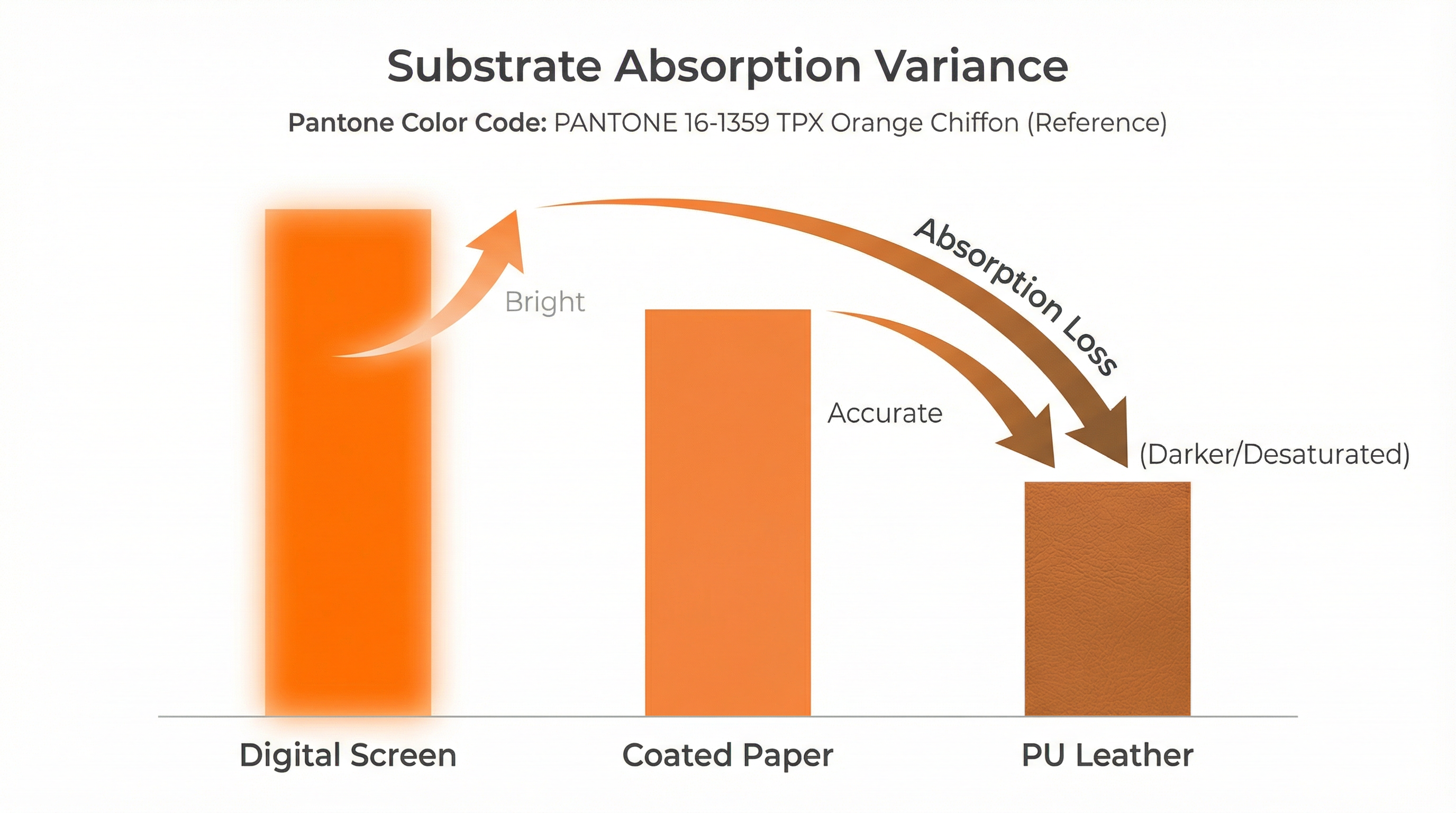

The Chemistry of Color Absorption

Color is another casualty of the digital mirage. Your monitor emits light (RGB); your product reflects light (CMYK/Pantone). But even within physical inks, the substrate dictates the final reality.

If you specify Pantone 16-1359 (Orange Chiffon), the ink formula is constant. However, printing that ink on a coated art card (which sits on the surface) versus a porous PU leather (which drinks the ink) yields two completely different visual results.

The porous material absorbs the pigment, lowering the refractive index and making the color appear darker and less saturated. A digital proof will never show this "sink-in" effect. It will show you the theoretical color, not the physical outcome.

The "Golden Sample" Necessity

This is why we push back when clients want to skip the physical sampling stage to save £100 or 5 days. The digital proof is a map, but the physical sample is the terrain. You cannot navigate the terrain solely by looking at the map.

For any order exceeding 500 units, relying on a PDF is not a calculated risk; it is a gamble. The only way to verify how light hits the foil or how the grain breaks the line is to hold the object in your hand.

Conclusion

The PDF is a contract of intent, not a guarantee of result. To ensure your brand assets survive the transition from pixels to atoms, you must respect the physical limitations of the medium. Treat the digital proof as a hypothesis, and the physical sample as the proof.